Graphene coatings

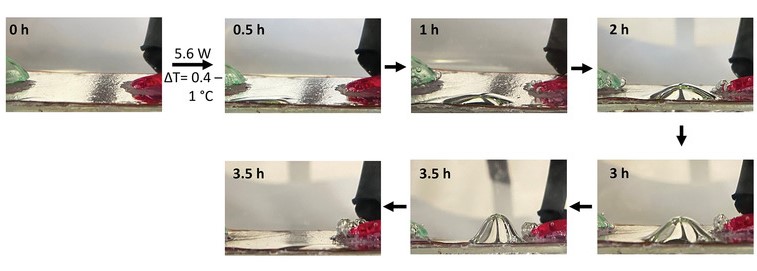

Membrane fouling in reverse osmosis modules leads to a decrease in water purification throughput and an increase in costs for membrane cleaning.[1] Feed spacers ensure a separation of the membrane layers but are also susceptible to fouling.[2] Thus, methods to protect feed spacers e.g. by chemical modification are urgently needed. Especially graphene, as an exciting new material, is an sp2-hybridized carbon allotrope[3] which has been intensively studied. Due to its extraordinary chemical, physical, mechanical and electrical properties, [3, 4] there is much interest in surface applications. Laser-induced graphene (LIG) can be easily generated on different polymer surfaces, using a CO2 laser in an environmentally friendly and cost efficient manner.[5-7] Its surface properties can be easily tailored by post-processing methods such as plasma treatment or chemical modification.[5, 6] The coated feed spacers show very good antifouling properties and even in commercial spiral modules, fouling was substantially reduced.[8] Some of the coatings showed ultrastable plastrons with superior antifouling properties, which offers further potential for future exploration.

Figure 1: Plastron growth on a superhydrophobic LIG surface over 3.5 h using Joule heating. Reprinted from [6].

Students working on this project: Emily Manderfeld

[1.] Ahmed, F. E. et al. Electrically conducting nanofiltration membranes based on networked cellulose and carbon nanostructures. Desalination 406, 60–66 (2017).

Collaborations: Prof. Arnusch, Ben-Gurion University of the Negev, Israel

[2.] Kim, Y. C. et al. Adverse impact of feed channel spacers on the performance of pressure retarded osmosis. Environ. Sci. Technol. 46, 4673–4681 (2012).

[3.] Singh, S. P. et al. Laser-Induced Graphene Layers and Electrodes Prevents Microbial Fouling and Exerts Antimicrobial Action. ACS Appl. Mater. Interfaces 9, 18238–18247 (2017).

[4.] Geim, A. K. et al. The rise of graphene. Nat. Mater. 6, 183–191 (2007).

[5.] Manderfeld, E. et al. Electrochemically activated laser-induced graphene coatings against marine biofouling. Appl. Surf. Sci. 569, 150853 (2021).

[6.] Manderfeld, E. et al. Thermoregeneration of Fouling‐Inhibiting Plastrons on Conductive Laser‐Induced Graphene Coatings by Joule Heating. Adv. Mater. Interfaces 9, 2201336 (2022).

[7.] Manderfeld, E. et al. Bacterial surface attachment and fouling assay on polymer and carbon surfaces using Rheinheimera sp. identified using bacteria community analysis of brackish water. Biofouling 38, 940–951 (2022).